What goes into an in-mold label? When producing labels there are several performance standards to be considered. What standards you ask? That depends on the application and how the product will be used.

Will it be used indoors or outdoors?

How long do you need the graphic to last?

Does it require special compliance such as FDA?

What chemicals will the product be exposed to?

Where and how does the label get placed in your tool?

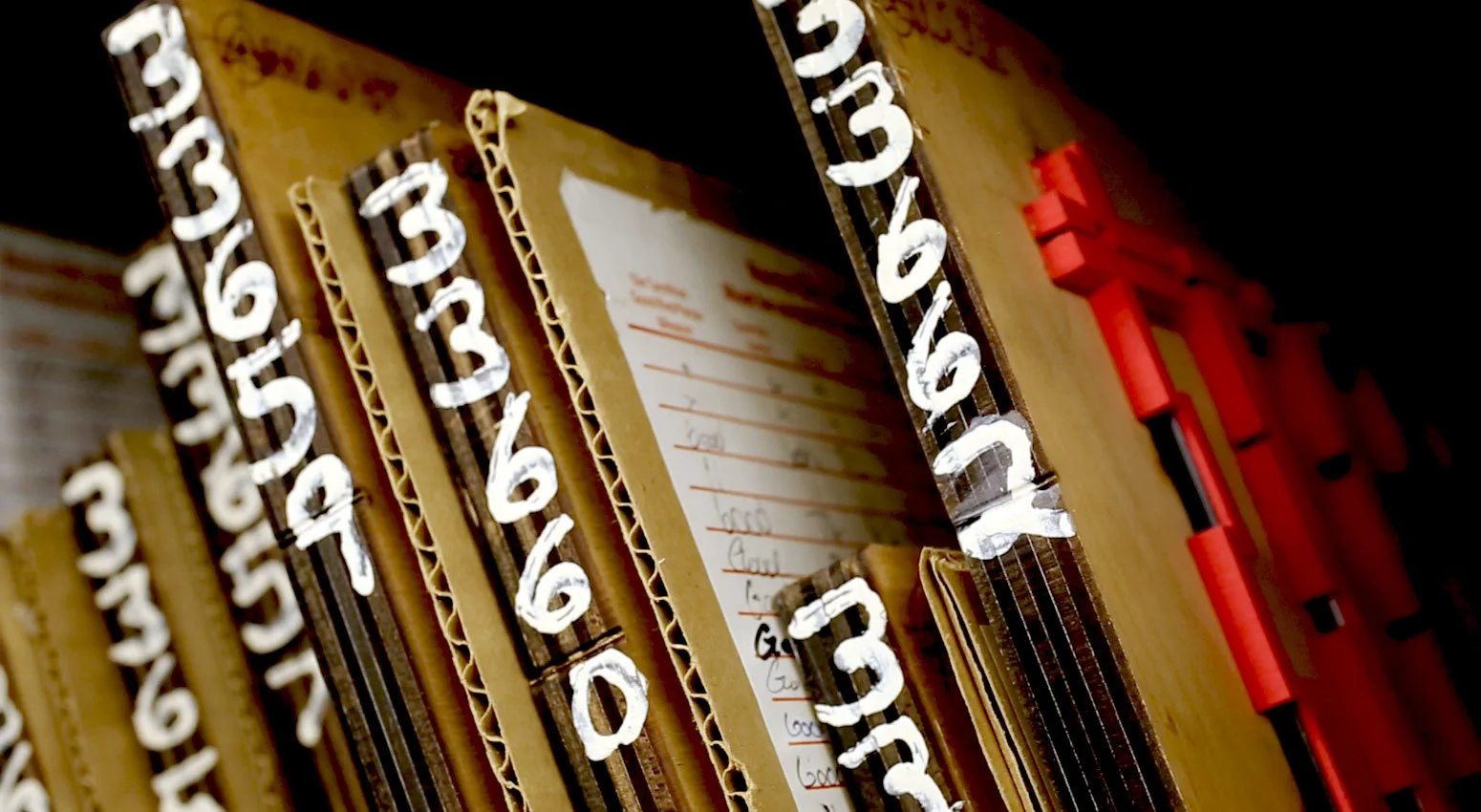

Every label printed at Romo Durable Graphics is tested before it goes out the door.

Static Value - a stack of in molds label cannot have so much static that they stick together - yet they need to accept a static charge to hold them in the tool during molding.

Ink Adhesion - some in-mold label materials can be tricky to print so keep a close eye on ink adhesion.

Ink Flexibility - the in-mold labeling process involves expansion and contraction so inks and clearcoats need to be flexible so they don't crack.

Chemical Resistance - the chemicals and cleaners will your product be exposed to under conditions.

Abrasion Resistance - Taber testing checks how long the inks will lastis a wheel determine are there certain abrasion standards that are required and if so should a Taber test be performed.

Stain Resistance - staining agents the product will be exposed to and need to resist.

Water Resistance - if the product is exposed to water - under what condition? High heat? Submersion? Dishwasher (commercial or residential)?

The performance standard questioned most often is outdoor durability. The best way to test this is to place the molded product in the field and check it periodically. The challenge is that most people don't have time to do that. The next best way to test is accelerated weather chambers that mimic sunlight, moisture, heat and cold. People can disagree on settings and how to interpret the results, but accelerated weather chambers are a good tool to speed up the testing process.

The research and development laboratory at Romo Durable Graphics performs a variety of these tests - always looking for ways to improve the products we manufacture. There are several different constructions that are designed to meet some specific needs of our customers. We will work with you to develop a product that meets your needs and performance standards.